PoligonSoft

Design Simulation: Casting Simulation Software Suite PoligonSoft

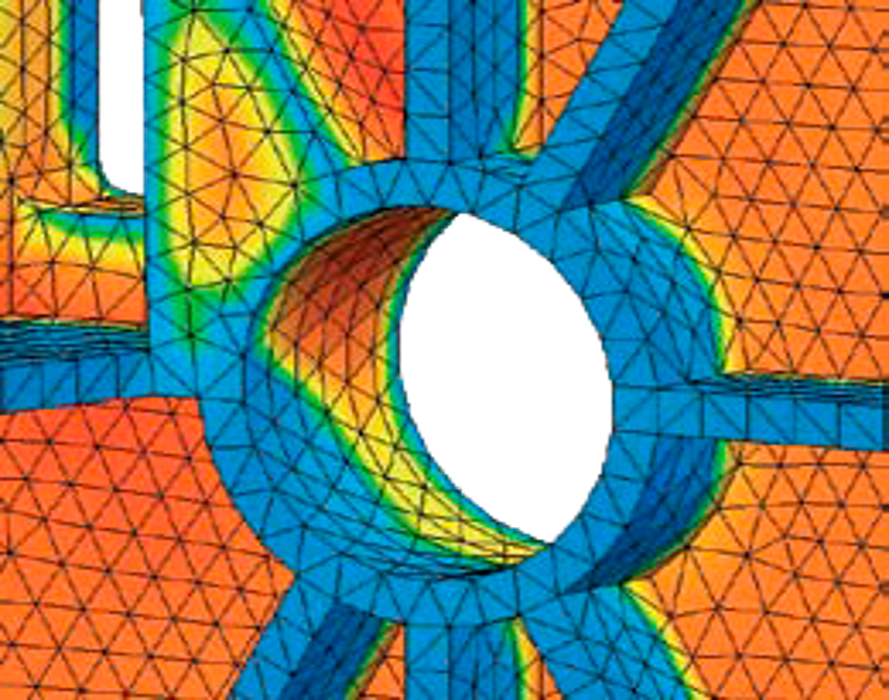

PoligonSoft is a professional tool designed for the creation and optimization of foundry technology. Utilizing the finite elements method, PoligonSoft performs comprehensive analyses of filling, crystallization, and stresses for various casting technologies and alloys.

Work with Complex Geometries

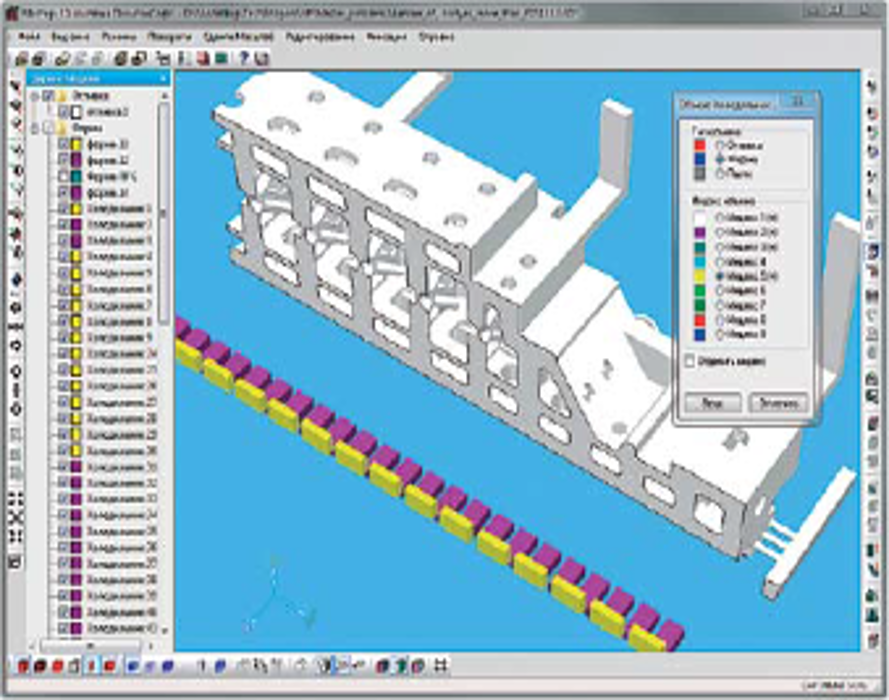

Thanks to the finite element approach, CSS PoligonSoft handles geometrical models of casting blocks with any complexity, consisting of multiple bodies of arbitrary shapes. Elements such as cooling plates, sand cores, support fillers, mold boxes, heat insulating materials, and melting equipment components can all be factored into the calculations to ensure high-quality foundry results.

The "Master-3D" module supports meshes in formats like Altair HyperMesh, ANSYS, ProCAST, Nastran, CATIA V5, NEU, GiD, and ISPA. Users simply need to upload the mesh model of the casting block, and "Master-3D" will automatically identify foundry elements and mold components, assigning the borders of the bodies' interfaces.

PoligonSoft Features

Filling of the mold

The "Euler-3D" module calculates the mold filling process with melt at constant or variable speeds through one or several sprues. It helps analyze:

A special parameter regulates the number of solid phases at which the melt flow stops, allowing simulation of the supercooled melt flow stop. Flowability reference data can be used as a master sample.

Cooling of the Foundry and Mold

The "Fourier-3D" module calculates temperature and phase fields, considering heat generation during crystallization. It solves filtration tasks, including pressure field simulations, and allows calculations for:

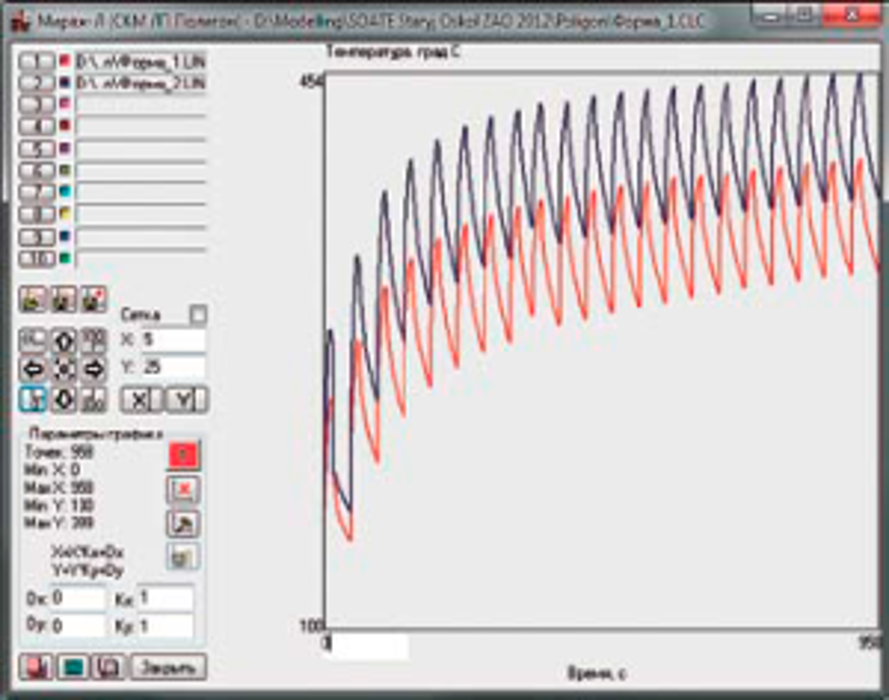

Cyclic Processes

In casting methods like press molding, it is crucial to determine the mold opening moment and temperature regime affecting product quality. "Fourier-3D" performs cyclic calculations, considering mold heating during previous cycles, cooling at mold joint moments, and core installations.

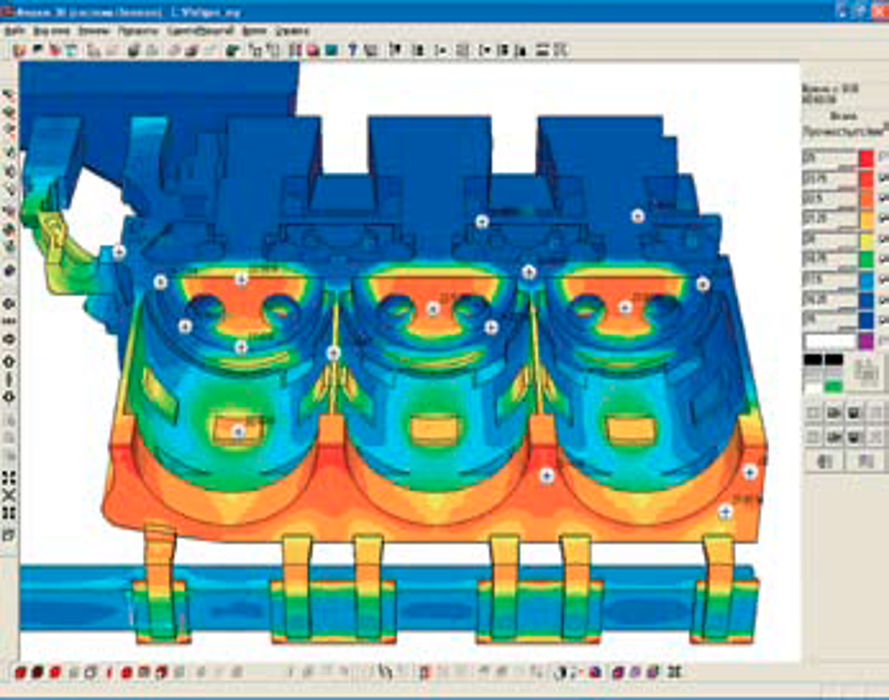

Warpage and Cracks

The "Hooke-3D" module calculates temperature stresses and strains during the cooling stage of the foundry and mold. Based on A. Ilyushin's theory of small elastoplastic strains and Newton's method, it calculates:

CSS PoligonSoft for Bulky Foundry

Using the finite element method, PoligonSoft effectively models large, thin-walled castings. With symmetry and multithreaded computation capabilities, the modeling process is efficient, and the required computing resources remain within the limits of standard office PCs.

Additional Possibilities

CSS PoligonSoft offers extensive criteria analysis capabilities. The "Criteria-3D" module allows calculation and analysis of properties such as structure, hardness, metal penetration, washing, cooling rate, and more. It includes a wide range of built-in functions, enabling users to create custom analysis criteria suited to specific production needs.